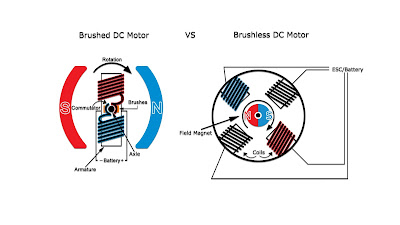

1. Brush-less Motor: DC Brush-less Motor uses a permanent magnet external rotor, three phases of driving coils, one or more Hall effect devices to sense the position of the rotor, and the associated drive electronics.

2. Brushed Motor: A Brushed Motor has a rotating set of wound wire coils called an armature which acts as an electromagnet with two poles. A mechanical rotary switch called a commutator reverses the direction of the electric current twice every cycle, to flow through the armature so that the poles of the electromagnet push and pull against the permanent magnets on the outside of the motor.

Brush-less DC Motor Pros

Brush-less DC Motor Pros

- Electronic commutation based on Hall position sensors

- Less required maintenance due to absence of brushes

- Speed/Torque- flat, enables operation at all speeds with rated load

- High efficiency, no voltage drop across brushes

- High output power/frame size.

Reduced size due to superior thermal characteristics. Because BLDC has the winding on the starter, which is connected to the case, the heat dissipation is better - Higher speed range - no mechanical limitation imposed by brushes/commutator

- Low electric noise generation

Brushed DC Motor Pros

Two wire control

Replaceable brushes for extended life

Low cost of construction

Simple and inexpensive control

No controller is required for fixed speeds

Operates in extreme environments due to lack of electronics

Two wire control

Replaceable brushes for extended life

Low cost of construction

Simple and inexpensive control

No controller is required for fixed speeds

Operates in extreme environments due to lack of electronics

No comments:

Post a Comment